Nearly half of Sweden’s electricity originates from nuclear power. That means, nearly every other lightbulb is powered by nuclear power! Although the Barsebäck Plant has been decommissioned, we would be happy to tell you about the process and other aspects related to the operation of a nuclear power plant.

What is energy

Energy is movement or the ability to move. Therefore, energy can neither be created nor utilized, but only converted to other forms. Nevertheless, for the sake of simplicity, terms such as energy source, energy generation and energy consumption are used.

Difference between energy and power

Energy and power are two terms that are frequently used interchangeably, but this is their definition: The amount of energy per unit of time required to perform a task is measured as power.

Energy = Power x Time

Energy is measured in joules (J), which are the same as a watt-second (Ws) and power is expressed in watts (W). The more power something uses, the greater the energy consumption per second (minute, hour...). Example: A lightbulb with the power of 60W consumes 60 joules per second.

For electrical energy (electricity), the kilowatt hour (kWh) unit is used. 1 kWh corresponds 3,600,000 joules.

Nuclear power in Sweden

Nuclear power plants currently generate 40% of the electricity in the country. Together with hydropower and wind power, nuclear power contributes to virtually emissions-free electricity generation.

In Sweden, the large-scale expansion of nuclear power took place during the 1970s and 1980s. Oskarshamn 1 has been in operation the longest and was commissioned in 1972. Forsmark 3 is Sweden’s youngest reactor and was commissioned in 1985. Today, there are eight active reactors in three locations:

Read more about nuclear power plants in Sweden

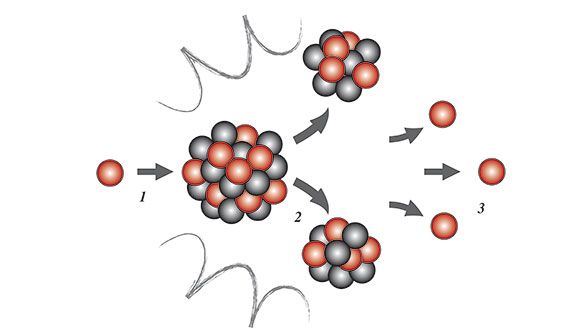

Nuclear fission

Nuclear power technology is based on the generation of heat through the splitting of uranium atoms. The splitting of atoms known as fission. Shooting a neutron at a uranium atom splits the atomic nucleus and releases new neutrons. These can, in turn, split other atoms and create a chain reaction. Fission releases heat that is used to generate electricity at a nuclear power plant

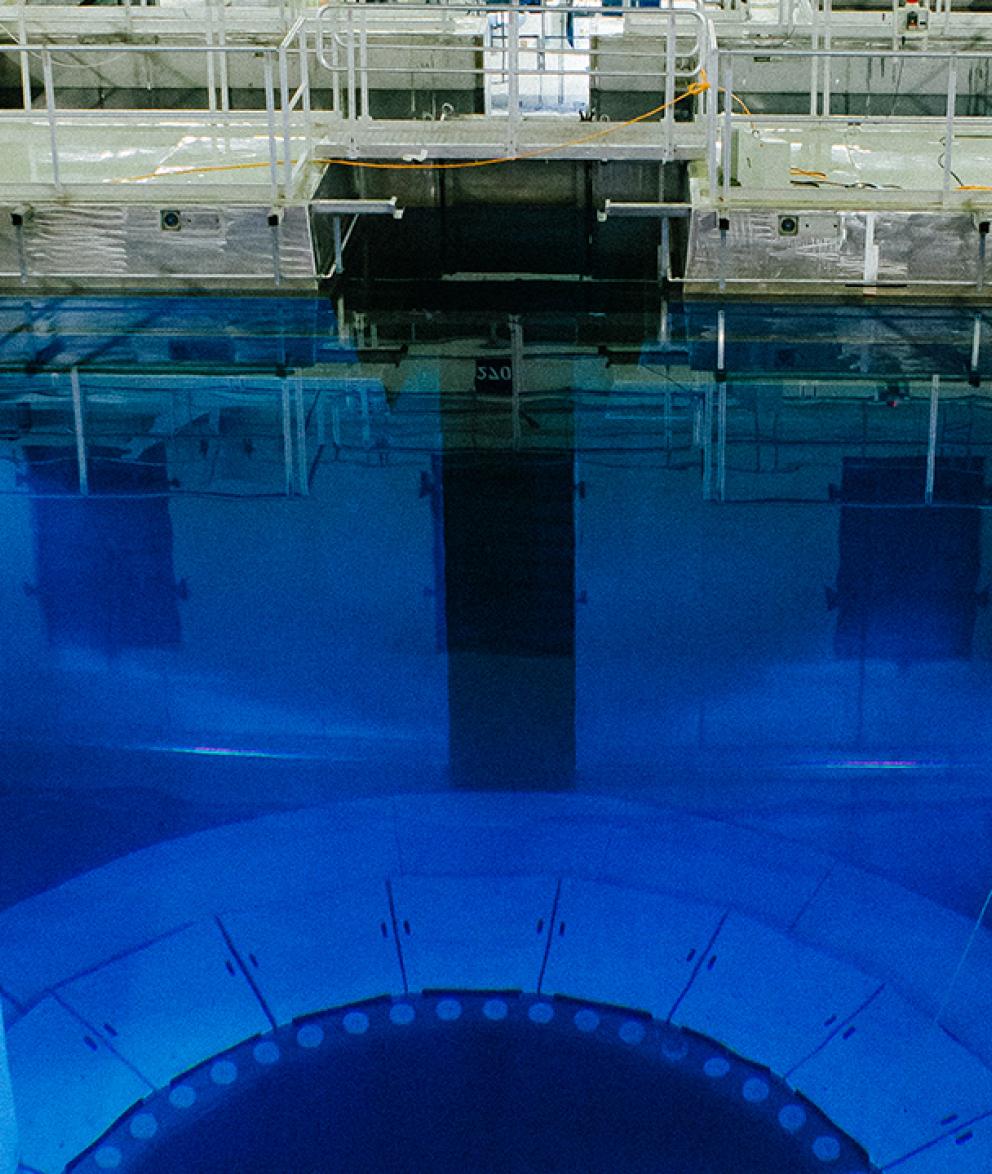

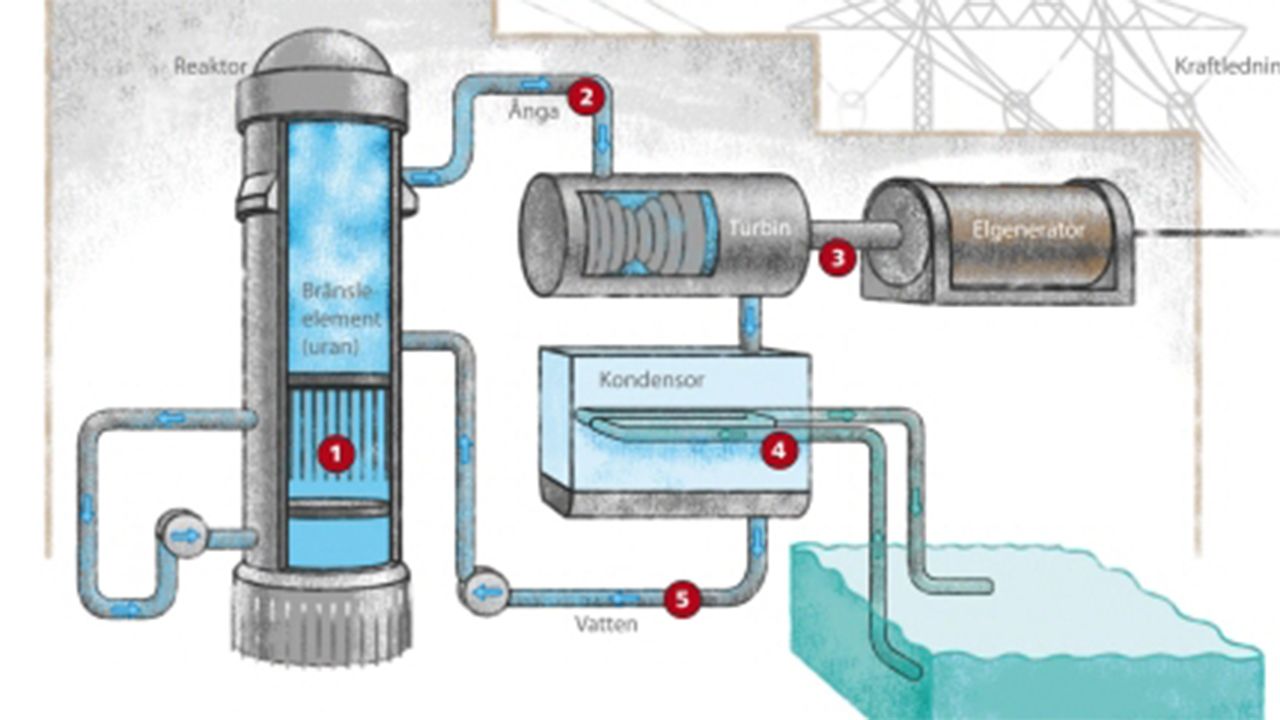

Electricity generation with a boiling water reactor

A nuclear power plant can be likened to an enormous water boiler. The uranium, which is the fuel in this case, heats the water, turning it into steam, which becomes pressurized and streams through turbines. The rotating turbine shaft powers the large electricity generator, which generates the electricity.

The principle is the same for power plants that use other types of fuel, such as coal, gas or oil. The advantage of nuclear power plants is that their production operations are free from carbon emissions. From an overall perspective, the impact on the environment and the climate is virtually nonexistent.

1. Fission in reactor releases heat that is used to boil water. A reactor is comparable with an enormous water boiler, where 1,000 liters of water reaches boiling point in one second, creating steam.

2. The steam is funneled to turbines. Under high pressure, the steam hits the blades mounted on the turbine shaft, which causes the shaft to spin at 3,000 revolutions per minute.

3. The turbine shaft is in turn connected to a generator that produces the electricity. The electricity is transferred from the generator to users via power lines.

4. The steam from the turbine is sucked down into a condenser, where it interfaces with cold seawater that is pumped into the condenser via numerous tube bundles. The steam comes into contact with the tube surfaces, cools down and turns into water again. The seawater is pumped back out to sea, 10–12°C hotter than when it was pumped in.

5. The water in the condenser is pumped back into the reactor to be boiled again. It takes about 10 minutes for the very smallest drop of water – a single water molecule – to complete a full cycle within the process.

The process water is thus held in a closed loop and the seawater coolant never comes into contact with the reactor’s steam.

Pumps and control rods regulate the output

There are two main methods of regulating the output of a reactor. Boron can also be used.

Main circulation pumps

Main circulation pumps are mounted on the inside or outside of the reactor vessel. Increasing power to the pumps allows for larger volumes of water to circulate in the reactor vessel, thus increasing the reactor’s output. Decreasing power to the pumps reduces the amount of water circulating through the reactor vessel, which thereby reduces the reactor’s output. This is also true if the pumps should stop working. This means that Swedish reactors are subcritical and therefore, their output cannot cause an uncontrolled meltdown.

Control rods

Control rods contain substances such as boron, which absorb neutrons to reduce nuclear fission or stop it entirely. The results depend on how long the control rods are inserted into the reactor core. For the purpose of a reactor trip, they are inserted fully to bring nuclear fission to an immediate halt.

Boron

Boron is an element that attracts neutrons. By changing the amount of boron in the process water, the reactor can be ramped up or down (nuclear fission increased or decreased).

How the electricity makes its way to you

Electricity is transported from nuclear power plants to society via the transmission grid, and regional and local grids. The higher the voltage, the further the electricity can be transported without incurring excessive energy losses.

Transmission grid

The transmission grid is owned by the government and covers all of Sweden, from north to south. The voltage in the power lines are 400,000 or 220,000 volts. The transmission grid runs between the major power plants and transformers located outdoors in the countryside. Operational reliability is important – if a power plant should stop functioning, there are always reserves in other power plants.

Regional grid

When the electricity reaches the region where it is to be used, it is transferred to a regional grid. There, transformers are used to step down the voltage to 40,000–75,000 volts in a series of steps, and the electricity is then transferred to industry and municipalities.

Local grid

To reach all the way to a household level, local grids are used. Here, the voltage is stepped down to 4,000–20,000 volts. Power lines can be seen in the countryside, but in cities, the cables are usually below ground. The voltage is stepped down to 230–400 volts before reaching Swedish households.

Uranium as a fuel

Uranium is one of the elements that the earth is made of. It occurs naturally in bedrock and comes in three different isotopes (various forms of the same element): uranium-234, uranium-235 and uranium-238.

Uranium-235 is the easiest to cool and is thus used as nuclear fuel.

Uranium is an energy-rich element. One kilogram of uranium contains as much energy as 90 tons of coal!

The production of nuclear fuel involves extensive work. The uranium is first crushed and then processed in several steps before the actual nuclear fuel elements are created.

Is uranium dangerous?

Before the fuel is used in a reactor, it emits very low levels of radiation and can be handled without using any special protective equipment. However, after its use in a reactor, it is highly radioactive.

Can the fuel explode?

The uranium in a nuclear reactor cannot explode, because it contains too little fissile material – only about 3% (try to run a car engine with one spoon of gasoline per liter of water, and you’ll get the idea). On the other hand, an atomic bomb must contain nearly 100% fissile uranium.

From ore to pellets

1. The uranium is crushed

Uranium ore is crushed in mines or open mines above ground. In Sweden, the uranium content is too low for the crushing to pay off. Consequently, we import the uranium we require – approximately 1,500 tons annually. Uranium ore is mainly crushed in Canada and Australia, as well as in Namibia, South Africa, Kazakhstan, Uzbekistan and Russia.

Natural uranium designated for Swedish reactors is imported from countries such as Australia, Canada, Namibia and to some extent, Russia. Swedish nuclear power plants impose environmental requirements on suppliers and producers of nuclear fuel. The crushing of uranium in mines is often fully automated due to the high radiation levels from radon in the ground.

2. A yellow powder

After crushing, the uranium ore is transported to a uranium processing plant where it is ground to a powder. The uranium content is increased by means of various processes and the result is a uranium concentrate in the form of a yellow powder. Uranium processing plants are often located close to the mine.

3. The uranium is converted and enriched

The uranium concentrate must be further processed before it can function as nuclear fuel. Through a process known as conversion, it is converted to uranium hexafluoride – a substance similar to paraffin.

The uranium hexafluoride is heated and enriched, which entails a process to increase the fissile uranium-235 content to about 3%, as required for nuclear fuel. Natural uranium comprises only 0.7% uranium-235. Five kilograms of natural uranium yields 1 kilogram of enriched uranium.

Uranium is enriched in countries such as France and the Netherlands. The uranium is transported from the mine by sea, road or rail.

4. Small black pellets

Following the uranium hexafluoride’s enrichment, it is cooled until it returns into a solid form and the converted into uranium dioxide. Finally, the uranium dioxide is used to manufacture the nuclear fuel, in the form of small cylinders, known as pellets. A nuclear power reactor contains approximately 15 million pellets.Each pellet provides as much energy as 800 liters of diesel oil!

5. Fuel element production

The pellets are stacked into long pipes that are bundled together into a fuel element. In Sweden, fuel elements are manufactured at Westinghouse in Västerås.

The number of fuel elements in a reactor depends on the type and size of the reactor. For example, Oskarshamn 3 contains 700 fuel elements, compared with Barsebäck 2, which contains 444 fuel elements.

Refueling during summer

In summer, the reactors are shut down for a short period of time, for what is known as a revision. This is when maintenance and improvements are implemented at the same time as new fuel is added. Fuel elements are used for about 5 years in a reactor before they are replaced.

In boiling water reactors, about one fifth of the fuel is replaced every summer. In terms of weight, this corresponded to approximately 15 tons per year for Barsebäck 2 when the plant was in operation.

Find out more

Find out how radioactive waste from nuclear power plants is handled.

Some insight into how we dismantle a nuclear power plant.