What it's all about!

The avoidance and reduction of methane emissions is an important topic that we have been working on for a long time. Compared to agriculture or natural methane sources, our storage facilities are known to have relatively low methane releases, and technical and organisational measures are effective and implemented to avoid these emissions as much as possible.

Since methane has a high climate impact in the atmosphere in the short term according to current findings, we have committed ourselves to controlling potential methane emissions even more intensively and to reducing them further accordingly in order to increase our contribution to the important decarbonisation of the energy sector here.

Climate change is now perceived as one of the greatest risks threatening our livelihoods on earth. The central cause of climate change is seen in the anthropogenic, that means man-made, emission of large quantities of greenhouse gases. Political institutions and also responsible industrial companies such as Uniper Energy Storage have therefore set themselves the goal of significantly reducing greenhouse gas emissions in order to slow down the current process of global warming.

After carbon dioxide, unburned methane released directly into the atmosphere contributes significantly to climate change. Although it has a shorter residence time in the atmosphere than CO2 due to chemical decay, it is thought to be responsible for about a quarter of current global warming (see IMEO 2021). More than half of global methane emissions are attributed to anthropogenic origins, of which about one third (35%) are from fossil fuel extraction and use: 23% from the oil and gas industry and 12% from coal mining. Further shares of anthropogenic emissions can be attributed to agriculture and livestock farming with about 40% and waste management with about 20% (see CCAC, UNEP 2021). Only a very small share of methane emissions attributed to the energy industry can be assigned to the distribution and storage of natural gas to supply end customers.

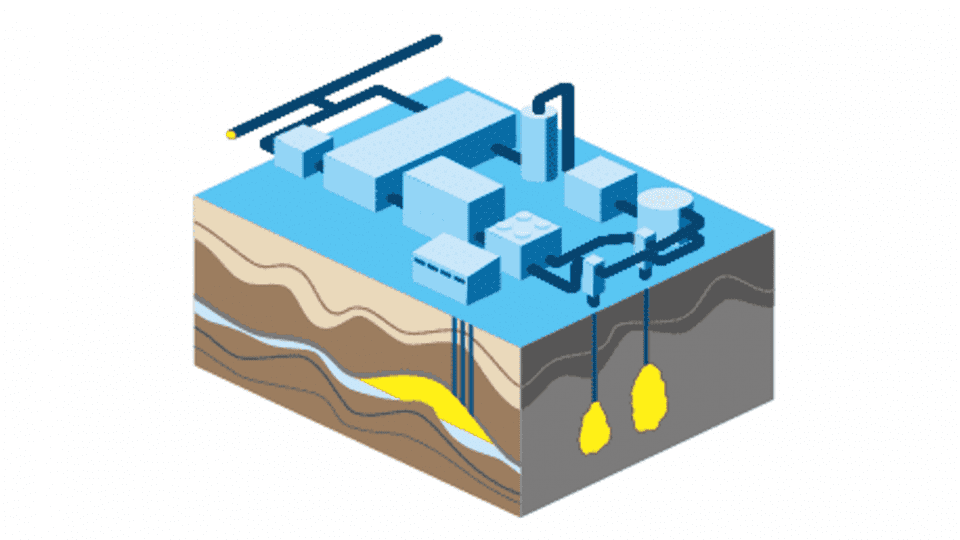

Methane emissions in the storage industry

Our focus is on minimising methane emissions that can arise from the use and especially the storage of natural gas.

Our storage facilities are always operated in accordance with the current state of the art and the highest safety standards and are technically tight. In accordance with legal requirements, they are also regularly inspected and adapted to current standards and modernised.

Regular plant operation nevertheless leads to unavoidable emissions, which we reduce to a minimum through intensive controls and constant improvement measures.

For example, we use processes that channel the natural gas into other parts of the plant or feed it into an energetic use through combustion when parts of the plant are depressurised. This becomes necessary in the event of an overhaul or an operational malfunction. In this way, the release of unburned methane - as far as required for safety reasons - can be prevented and resulting CO2 emissions minimised.

We make great efforts to detect and remedy even minor leaks at an early stage. For this purpose, regular recurring campaigns are carried out to check the function and leak tightness of all essential plant components. These activities are also referred to as Leak Detection and Repair (LDAR). Leaks detected in the course of LDAR campaigns are repaired immediately, taking into account and balancing the minimisation of overall emissions due to the repair, the safety of plant operation and ensuring security of supply for end consumers.

At the same time, we are working on the continuous further development of techniques and methods of emission monitoring and leakage detection as well as technologies to avoid methane emissions. We see this as part of our operator responsibility.

LDAR (Leak Detection and Repair) refers to the operational activities for detecting and eliminating leaks in the gas infrastructure. For this purpose, different measures are carried out that are coordinated in terms of time, method and scope of investigation.

In addition to the permanent monitoring of the regular operating pressures of our storage facilities via the control room, regular inspections are carried out at short intervals to check the proper operation of key facility components and the tightness of the facility. Observed malfunctions, faults or leaks are remedied promptly so that possible methane gas releases do not go undetected and are stopped. At further coordinated intervals the plant components are additionally subjected to more elaborate leakage tests, which show a greater sensitivity of the applied leakage detection procedures. In addition, techniques such as laser-based remote gas detection systems are repeatedly used to obtain indications of emission sources that are difficult to detect, for example due to their accessibility. These are then specifically followed up.

Our responsibility

As part of OGMP 2.0, we have voluntarily committed to further and continuously reduce our methane emissions for climate protection.

At the end of 2020, Uniper Energy Storage joined the Oil & Gas Methane Partnership (OGMP 2.0), an international initiative of companies in the oil and gas industry led by the United Nations Environment Programme (UNEP). The initiative has set itself the goal of developing and implementing a uniform standard "OGMP 2.0" for recording and reporting methane emissions in the oil and gas industry and, if possible, establishing it worldwide. The standards developed should help to ensure that emissions are recorded reliably and comparably in the future, that transparency of methane emissions caused by the use of fossil fuels is created and that these emissions are minimised more quickly, specifically and effectively.

In addition, Uniper Energy Storage has voluntarily committed to reducing its annual methane emissions by 45% by 2025 compared to 2015, among other things by implementing various technical optimisation measures.

Uniper Energy Storage has reported the majority of its methane emissions from self-operated storage facilities according to reporting level 4 for the years 2020 and 2021, thus achieving the Gold Standard according to OGMP 2.0.

The current report "An Eye on Methane: International Methane Emissions Observatory 2022 Report" can be found here.

The Oil & Gas Methane Partnership (OGMP 2.0) is an initiative of the Climate and Clean Air Coalition, launched by the United Nations Environment Programme in partnership with the European Commission, the UK government, the Environmental Defense Fund and leading oil and gas companies. Nearly 100 companies with assets in more than 60 countries on five continents have joined OGMP 2.0, which is the new reporting framework that will improve the reporting accuracy and transparency of anthropogenic methane emissions in the oil and gas sector.