Hydrogen storage - Why?

Hydrogen makes the immense energy storage capacities that lie in the nationwide natural gas infrastructure available for renewable energies. The chemically bound energy in the form of hydrogen is available to various markets - such as the electricity and heating market, industrial applications and mobility. The need for storage capacities is growing with the expansion of renewable energies.

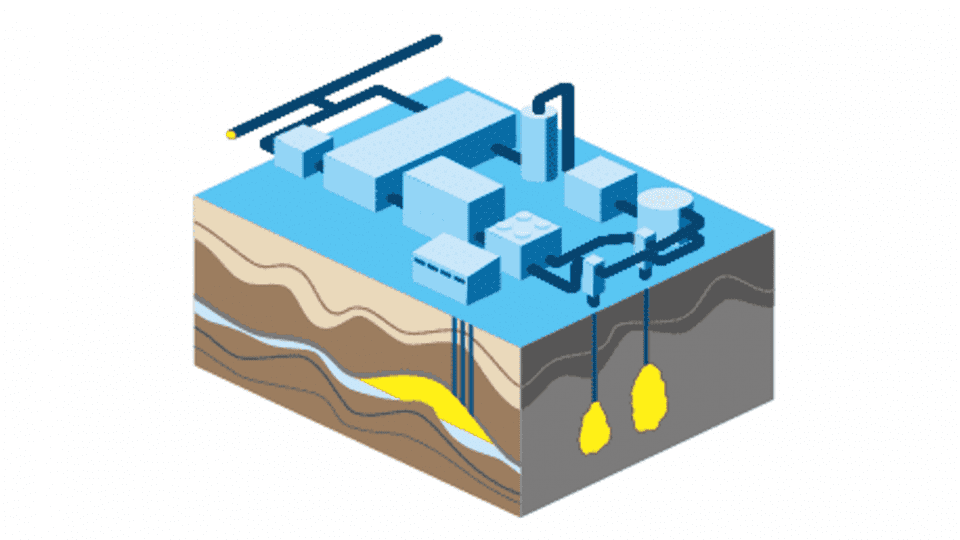

Underground storage of natural gas/hydrogen gas mixtures can create large-volume energy storage facilities that lead to greater flexibility in gas and energy supply.

With our HyStorage research project, we are testing the integrity of porous rock storages with regard to hydrogen storage together with our partners Open Grid Europe, RAG Austria, SEFE and NAFTA.

Project description

HyStorage is about investigating the influence of different hydrogen concentrations on porous rock formations and thus testing the suitability and integrity of pore storage facilities for storing hydrogen.

At the Bierwang underground gas storage site, natural gas/hydrogen gas mixtures are injected in order to be able to determine the biogeochemical processes in the subsurface. This will allow predictions to be made about the longevity and integrity of the reservoir. The research results and conclusions obtained with this project represent essential information for the operational behaviour of underground gas storage facilities and are to be transferred to the German and European underground storages if possible.

A smaller former natural gas reservoir - independent of the existing Bierwang natural gas storage facility - will be used for the test.

In three project phases, three different natural gas/hydrogen gas mixtures with 5 per cent, 10 per cent and 25 per cent hydrogen content in the natural gas will be injected into the former natural gas reservoir and then withdrawn after a three-month standstill period in each case.

The first cycle with 5% hydrogen serves as a basic check of the feasibility of the application, the second establishes comparability with other international industrial projects and the third is a continuation and preparation for future, higher hydrogen concentrations, but also for possible hydrogen peaks due to concentration fluctuations in the natural gas infrastructure.

Extensive investigations, regular measurements of the material and gas composition as well as evaluations and analyses of the data will take place throughout the duration of the project.

The planning and implementation of the project is carried out in close coordination with the responsible mining authority.

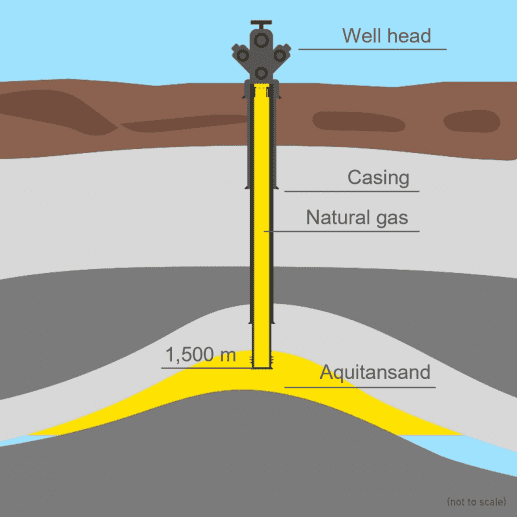

1) Status of the well

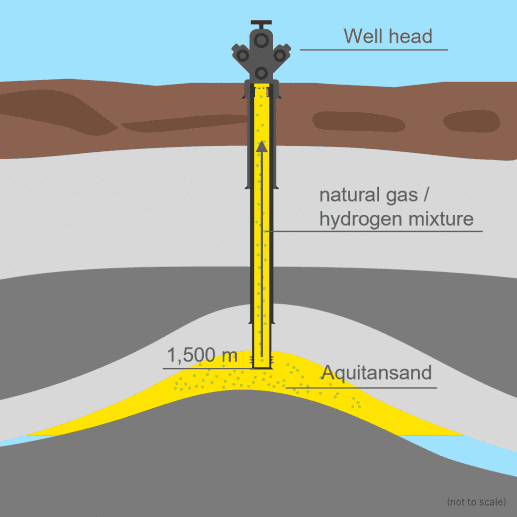

For the HyStorage project, we are using the existing BW B6 well. The borehole connects the reservoir with the surface. Only the wellhead of the borehole is visible.

The borehole passes through various rock layers until it hits the target horizon at a depth of approx. 1,500m and is secured by various casings.

For the HyStorage experiment, the Aquitansand storage horizon is used. This horizon is delimited above and below by thick impermeable overburden. There is no connection to our Bierwang natural gas storage facility.

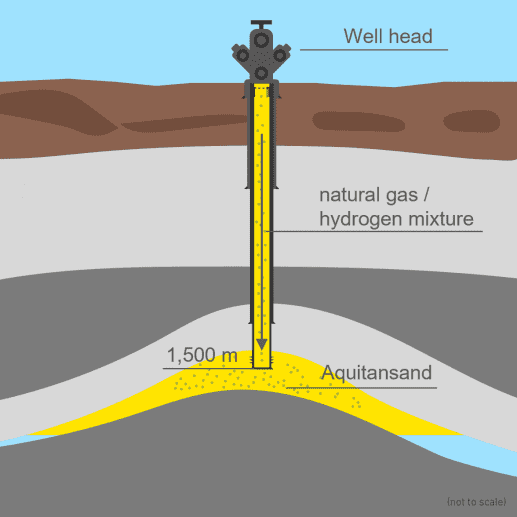

2) Injection phase / service life

In three project phases, a natural gas/hydrogen gas mixture with 5%, 10% and 25% hydrogen, respectively, is injected underground and then pumped up again after a three-month service life period in each case.

Specific material tests in advance have ensured that all materials and components used are designed for test operation with hydrogen. Extensive investigations and regular measurements of the composition of substances and gases will be carried out during the project.

To test the suitability of components and materials of various underground facilities under real conditions, additional investigations will take place during the project phases. This includes, for example, the construction of two temporary test containers for testing steels, cements and drilling core materials next to the wellhead or also material testing in the borehole.

3) Withdrawal phase

During the withdrawal phase, the natural gas/hydrogen gas mixture is withdrawn through the well.

The recovered gas mixture is analysed on the surface to be able to make statements about underground biogeochemical processes. In this way, forecasts can be made about the longevity and integrity of the reservoir.

The research results and conclusions obtained with this project represent important information for the probable operational behaviour of porous rock underground gas storage facilities in connection with hydrogen components in natural gas.

After analysis, the natural gas/hydrogen gas mixture is diluted to such an extent that it can be fed into the existing natural gas infrastructure.

When? |

What? |

|---|---|

2022 |

Establishment of the specialised gas facility for the storage test on a designated drilling site at Uniper Energy Storage's Bierwang site. |

May 2023 |

Start trial operation |

September 2023 |

First injection of the natural gas/hydrogen gas mixture |

In three phases of operation, three different natural gas/hydrogen gas blends with 5 percent, 10 percent and 25 percent hydrogen in the natural gas, will be injected into the former natural gas reservoir and then withdrawn again after a three-month holding period. Extensive investigations, regular measurements of the material and gas composition, and evaluations and analyses of the data will take place during the project. |

|

2025 |

End of project |

A strong Team

To realize the HyStorage project, the companies Uniper Energy Storage GmbH, Open Grid Europe GmbH, RAG Austria AG, SEFE Securing Energy For Europe GmbH and NAFTA a. s. have joined forces to form a consortium. Other interdisciplinary partners from industry and science, such as Voest Alpine, Vallourec, Isodetect and the Technical University of Clausthal, provide technical and scientific support for the project.

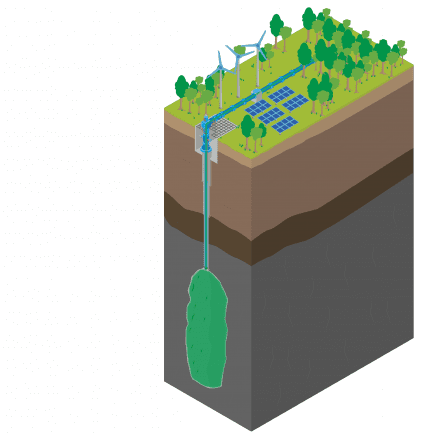

Our other hydrogen projects

The HPC Krummhörn project aims to test the construction and operation of a 100% hydrogen storage facility under real conditions. During the test operation, we check equipment, materials and substances for H2 compatibility and gather experience regarding technology and operation in the storage of hydrogen. For this purpose, we are using our salt cavern storage facility in Krummhörn in northern Germany, which has not been used commercially since 2017. The demonstration plant is scheduled to go into operation by 2024.