Storing hydrogen - Why?

Being able to store hydrogen in large quantities means making renewable energy sources flexibly available. This is essential for a decarbonised energy system in the future and the development of a hydrogen industry in Germany.

We have been using large-scale storage facilities for the safe storage of natural gas for decades.

We are testing underground hydrogen storage in caverns with the HPC Krummhörn project.

The Background

The Background

The storage of hydrogen in salt caverns has so far only been used sporadically in the USA and the UK. Especially for operational use with cyclical injection and withdrawal, there is not enough experience in Germany. The manufacturers do not have sufficient specifications regarding material compatibility and certifications for operation with hydrogen.

This is why we test geological conditions and all plant components for their compatibility with hydrogen in a specially constructed pilot cavern.

The experience gained here will then form the basis for larger-scale projects and the foundation for the construction of further, then commercial, hydrogen caverns at other locations.

Project description

Project description

- Commissioning planned until 2024

- Storage volume of minimum 200,000 m³ hydrogen

- Testing the operation and technology of 100% H2 storage in real environment

- Understanding of the approval procedures and requirements

- Investigation of materials, underground and above-ground installations, and the functionality of individual components in H2 storage operation.

- Development of a storage solution for green hydrogen on a commercial scale

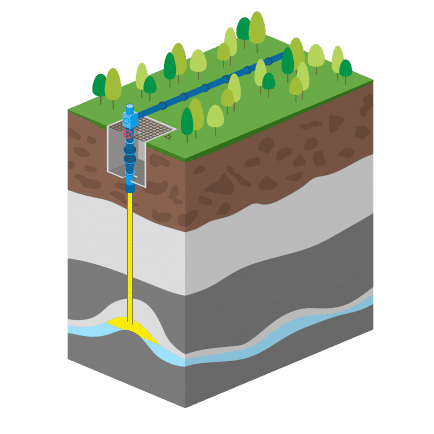

The HPC Krummhörn project aims to test the construction and operation of a 100% hydrogen storage facility under real conditions. For this purpose, we are using our salt cavern storage facility in Krummhörn in northern Germany, which has not been used commercially since 2017. Here we are constructing a new salt cavern with a geometric volume of about 3,000 m³ using an existing drilling. We are focusing on the evaluation of new caverns in order to avoid restrictions from the previous use with natural gas.

During the test operation, we check equipment, materials and substances for H2 compatibility and gather experience regarding technology and operation in the storage of hydrogen. The demonstration plant is scheduled to go into operation by 2024. We are investing around €10 million in this green future project with a storage volume of minimum 200,000 m3 of hydrogen.

The Lower Saxony Ministry for the Environment, Energy and Climate Protection is funding the project as a pilot and demonstration project for the hydrogen economy (within the framework of the Hydrogen Guideline) with €2.375 million.

1) Status of the borehole

Evaluate the status of the borehole and perform a two-stage gas tightness test.

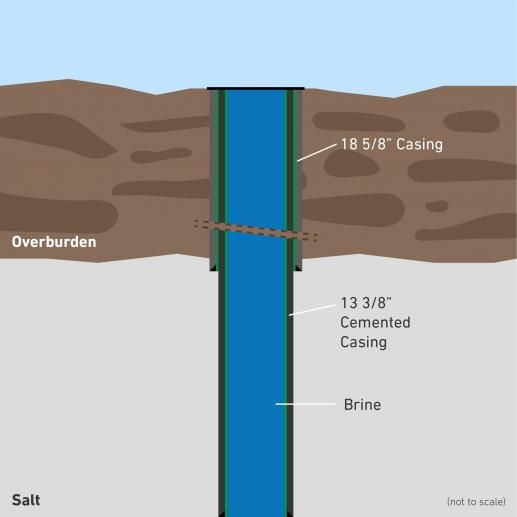

For the construction of the H2 pilot cavern, we are using the existing storage well K6. Before starting work on the cavern site, we examine the existing components of the well in various material tests to determine their suitability for hydrogen storage operation. First, we use a workover rig to restore access to the open hole and create a defined continuous borehole diameter in the uncased borehole area that is part of the test area. In addition, we subject the well to a two-stage gas tightness test using the test media nitrogen and hydrogen.

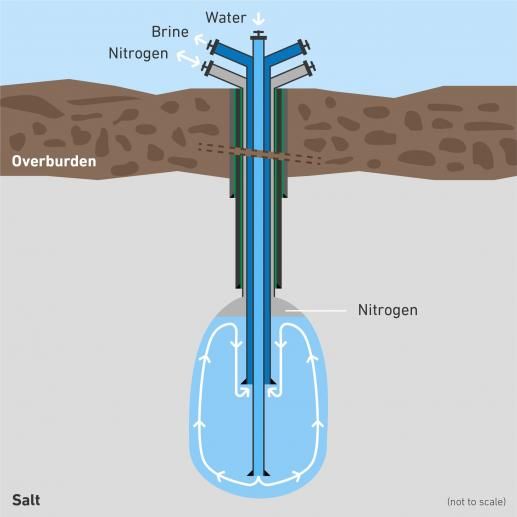

2) Solution mining phase

Creating a cavern by leaching

During the brine phase, we will create a pilot cavern with a geometric void volume of approximately 3,000 m³ in the lower section of the well. This configuration allows for a possible later re-solving to enlarge the cavern in order to be able to use the cavern commercially for hydrogen storage after the pilot phase. For the brine-out phase, the necessary brine-technical installations will be installed and the cavern will be connected to the brine station via the field pipeline system. In order to specifically develop the cavern shape, we use nitrogen as blanket medium.

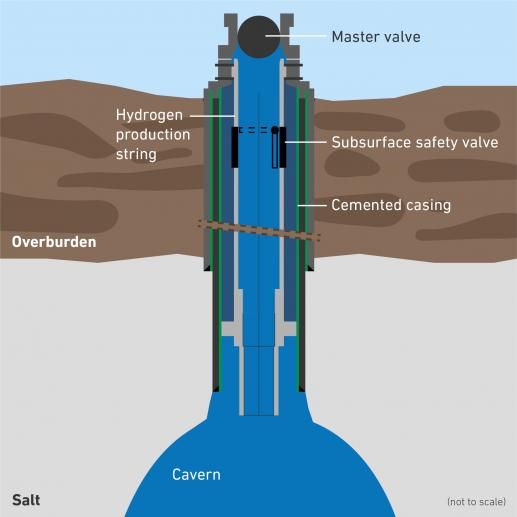

3) Hydrogen leak test

Hydrogen leakage test and installation of a hydrogen storage completion

After the pilot cavern has been built, the solar installations will be removed and the cavern will be subjected to a new leak test with hydrogen as a medium. The test pressure corresponds to the later storage operating pressure. Afterwards, we convert the cavern for hydrogen operation. In this context, we install, among other things, a hydrogen production pipe tour with special underground components and a hydrogen wellhead. On the surface, we connect the cavern via the field pipeline system to the storage station, where the hydrogen storage components are installed.

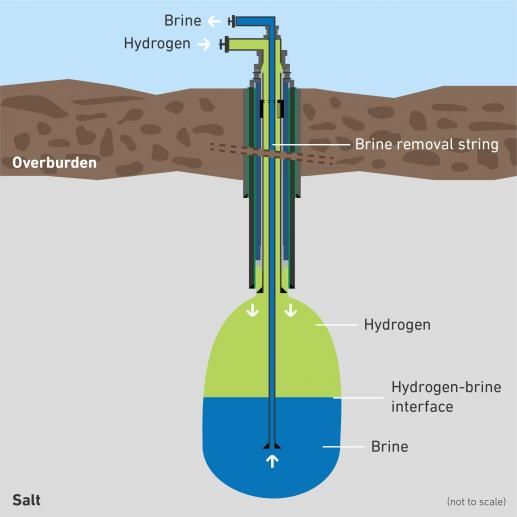

4) Initial hydrogen filling

Initial hydrogen filling and subsequent pilot storage

To evaluate the various planned tests, the operating conditions and the hydrogen suitability of the components, we install appropriate measuring equipment. After commissioning all components, we then fill the cavern with hydrogen for the first time. The brine that is still in the cavern at this point is displaced by the hydrogen and brought to the surface via a brine drainage line. After complete filling, the brine drainage line is removed from the cavern under pressure using a so-called snubbing system. The operating phase of the hydrogen pilot cavern then begins.

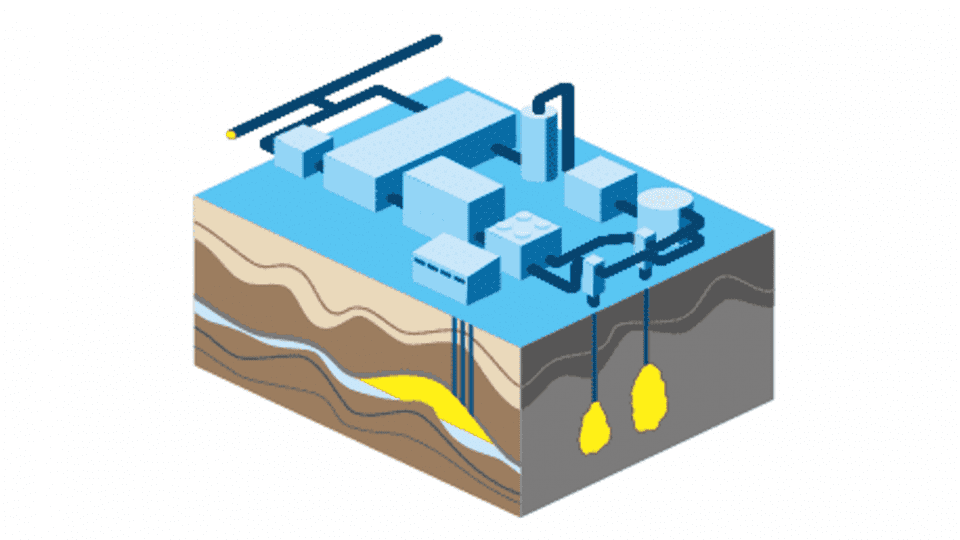

The surface facility

Functions of the surface facility

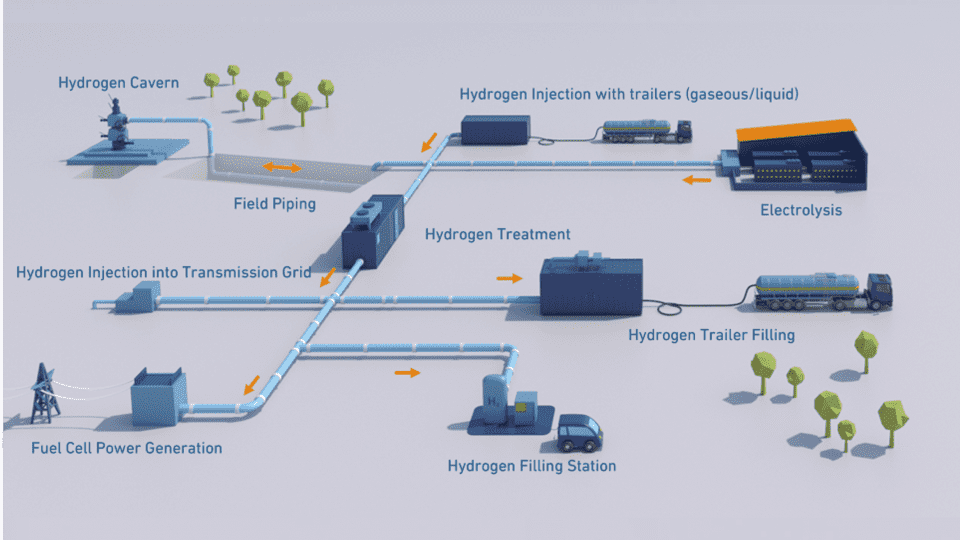

We prefer to store green hydrogen in our H2 test cavern, which is produced, for example, by electrolysis from green electricity generated by nearby wind turbines. Alternatively, it can be delivered by truck in liquid or gaseous form. The hydrogen is first compressed to a maximum cavern pressure of 250 bar and then transported to the cavern via the field pipeline. We store the hydrogen for our investigations in the pilot cavern for a period of up to 2 years.

H2 processing has several functions. In the first step, we analyze the hydrogen to determine changes that have occurred during the storage phase in the cavern. Furthermore, the moisture is removed from the hydrogen. Two processes are used here (adsorption and absorption), which are compared in the test phase. In the end, we free the hydrogen from possible biological, sulfur- and hydrocarbon-containing residues and make it available to the customers.

After processing, we plan to supply the hydrogen to various customers:

- Metering into the existing natural gas pipeline network

- Gaseous filling in H2 trailers

- Generation of electricity in a fuel cell

- Use in a hydrogen filling station

Since the consumers operate in different pressure ranges, the gas pressure is regulated and adjusted in each case before feeding.

The hydrogen pilot cavern is connected to the storage station via an existing natural gas field pipeline. As part of the planned test operation, we are repurposing the field pipeline and using it for operation with hydrogen. During the test operation, we will subject the field pipeline to a test and inspection program to gain knowledge of the influence of hydrogen on the installed components and materials.

Energy Transformation Hub Nordwest

With the Energy Transition Hubs, Uniper has created technology and exchange platforms - our Energy Transformation Hubs. At these hubs, we are engaging with both local and national stakeholders, and working with our partners in business and industry to reduce CO2 emissions, secure the energy supply for the future and drive forward sector coupling. At selected locations, we are working with our partners on innovative solutions focusing on hydrogen and other climate-friendly gases.

One of these locations is Krummhörn, which is part of the Energy Transformation Hub Nordwest. The Energy Transformation Hub Nordwest bundles Uniper's major projects for supply security and hydrogen in Wilhelmshaven and the surrounding area.

Our other hydrogen projects

In our HyStorage research project, we are testing the integrity of porous rock storages for hydrogen storage. At our Bierwang site in Bavaria we examine the influence of different hydrogen concentrations on porous rock formations. The measurement data and results generated, will help to fundamentally assess the suitability of the storage location for the future storage of hydrogen.