Gas storage today

Within Uniper, all expertise in underground gas storage across Europe is pooled in Uniper Energy Storage GmbH. We operate natural gas storage facilities in Germany, Austria and the UK with a working gas capacity of over 7 billion cubic meters. Our storage facilities ensure the year-round supply of gas for consumers. They are the link between continuous gas production and seasonally changing gas sales over the course of the year - for example, the demand for natural gas for the heating market is significantly higher in winter than in summer. Today and in the future, our gas storage facilities make a key contribution to security of supply in case of high demand peaks and to overcoming supply interruptions.

In cooperation and in constant dialogue with our customers, we continuously improve our gas storage products and our services. We offer comprehensive and innovative solutions that are individually optimised to meet the needs of our customers. Our products are offered to all market participants on a non-discriminatory basis and are sold one hundred percent digitally within the framework of online auctions via our storage portal.

Hydrogen storage in the future

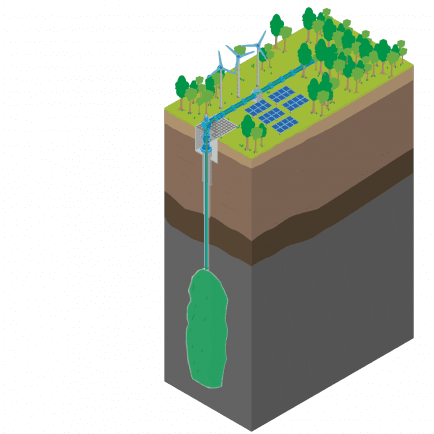

The share of renewable energies in power generation will continue to grow in the future, but they are not available all the time and in all places. This is where hydrogen comes into play. The transport of large quantities and the short- and long-term storage of hydrogen enables access to green energies independent of production in terms of time and location, especially when demand peaks exceed production.

Hydrogen has great potential to make an essential contribution to decarbonisation and enables the coupling of the energy sectors electricity, heat and transport.

Security of Supply and Innovative Gas Storage Technologies

With the publication of the National Hydrogen Strategy in 2020, the BMWK has defined a guiding basis. This provides the appropriate framework for the development of Germany's future energy infrastructure and the decarbonisation of German industry. Building a future hydrogen infrastructure is of particular importance in the context of an often geographic and temporal decoupling of the production and use of green hydrogen. It must be taken into account that hydrogen grids ensure the geographical decoupling of supply and demand. For temporal decoupling and flexibilisation, it is however essential to integrate large-scale storage options into an H2 infrastructure. The temporal balancing of supply and demand must be possible in both the short and medium term. In contrast to existing natural gas storage facilities, which are used in the first place for seasonal compensation, hydrogen storage facilities must also primarily compensate for the day-cycle and weather-related load profile of the green hydrogen production capacities. Uniper Energy Storage has well over 40,000 GWh of storage capacity in cavern storage facilities in northern Germany, which are in general also suitable for storing hydrogen.

Our focus

Decarbonization

Our goal is to operate our plants carbon-neutral by 2035. Hydrogen and the flexible use of renewable energies are central building blocks of the decarbonized energy world to come. So we are currently investigating the possibilities for storing hydrogen and green gas in our gas storage facilities.

Customer centricity

We attach great importance to close customer contact and are constantly developing our innovative product and service portfolio together with our customers in accordance with their individual needs. We market our storage products via online auctions, which we run on our digital storage portal.

Security of supply

Our gas storage facilities make an important contribution to the flexible and secure supply of energy. In an energy market that is relying more and more on renewable energies, gas storage facilities have a key role to play.

Responsibility for Employees and Environment

Uniper Energy Storage is aware of its responsibility and takes it very seriously. We strengthen local infrastructure and protect landscapes and natural habitats. An essential foundation for our success is the trust of our local communities also of our customers, employees and the wider public. This trust in the sustainability of our activities gives us the necessary backing in society for the construction and operation of plants as well as for innovation and growth. We have already been working on reducing our methane emissions for several years, for example, and would like to become even better in this area.

At Uniper Energy Storage, the Health, Safety, Security, Environment & Quality (HSSEQ) management system and the management of the public authorities are located as a central unit directly under the management. HSSEQ and responsible action have top priority throughout Uniper and thus also for us. "Zero tolerance for accidents" is part of our identity and firmly anchored in the goals of top management. All safety-relevant plant units are approved by the mining authorities and have been inspected by experts. Safety concepts as well as alarm and hazard prevention plans are available for all sites and have been coordinated with the responsible authorities and the external emergency services.

Careers

Do you want to shape the energy world of the future? Do you want to take on personal responsibility, make an important contribution to security of supply and develop yourself even further?

At Uniper Energy Storage GmbH, we offer a wide range of opportunities in various areas of commercial and technical work. You can expect a motivated team with nice colleagues, flexible working hours and extensive training opportunities. We live diversity and inclusion and the work-life balance of our employees is important to us as well. We welcome interest from professionals, students and prospective trainees.

Meet the Team

Around 170 dedicated employees from a wide range of disciplines work for Uniper Energy Storage. Whether as engineers, geologists, sales or administrative staff - everyone contributes to the company's success. We work together in an interdisciplinary way and hand in hand to achieve our goals.

Whether at our storage sites in northern and southern Germany, Austria or the UK, or at our offices in Düsseldorf, Vienna and Holford - all our employees play their part in ensuring a secure gas supply throughout the year.

Get to know some of our colleagues from different areas and find out what motivates them and what they value so much about their work for Uniper Energy Storage.

Sebastian Boor, Project Manager Cavern Operations

"What I appreciate is the collaboration in a multi-disciplinary team, as well as the opportunity to shape the development of new technologies "

Meike Nordhausen, Market Analysis & Pricing Manager

"I very much appreciate the open and unconditional cooperation and communication at Uniper. This always promotes very good solutions."

Doug Waters, Managing Director of Uniper Energy Storage

"I am very proud to work with highly motivated and qualified people who give their best every day and together we aim to play our part in a safe and reliable energy transition."

Gavin Williams, Site Operator

"I enjoy working for Uniper Energy Storage as I get to work with a focussed, hard-working team and I also get to run a State of the art fully automated plant."

Werner Höhne, Maintenance Skilled Worker

"The technology at gas storage and compressor stations inspires me every day anew. I have been well welcomed and integrated at the Bierwang station since my first day."

Susann Klause, Project Manager Storage Integrity & Development

"I really enjoy working for Uniper Energy Storage. I particularly appreciate the open interaction with each other and the constructive and uncomplicated cooperation in the team."

We are Uniper

Christoph Borgmeier works in mechanical maintenance at the Epe natural gas storage facility.

Today more than ever, gas storage facilities stand for security of supply. In Epe, North Rhine-Westphalia, Uniper operates a cavern storage facility. Christoph Borgmeier works here in the area of mechanical maintenance and organizes the maintenance of the facilities in the cavern field. Find out more about his work and the Epe gas storage facility.

Partners and Network

Uniper is in constant dialogue with relevant partners and associations. By providing regular information on our services and making adjustments in line with the latest market, regulatory and legal conditions, we are able to offer our customers the best possible and most advanced service at all times.

With our association activities, we are also working to ensure that the system value of our natural gas storage facilities is more strongly perceived and rewarded. The system value is reflected, for example, in the form of avoided costs for additional investments in transport capacities.