| Data | Barsebäck 1 | Barsebäck 2 |

|---|---|---|

| Construction start | 1971 | 1973 |

| Commercial operation | 15 maj 1975 | 1 juli 1977 |

| Gross capacity | 615 MW | 615 MW |

| Permanent shutdown | 30 november 1999 | 31 May 2005 |

| Electricity supplied | 93,8 TWh | 108 TWh |

Technical data Barsebäck

|

Net output (electricity) |

600 MW |

|

Reactor type |

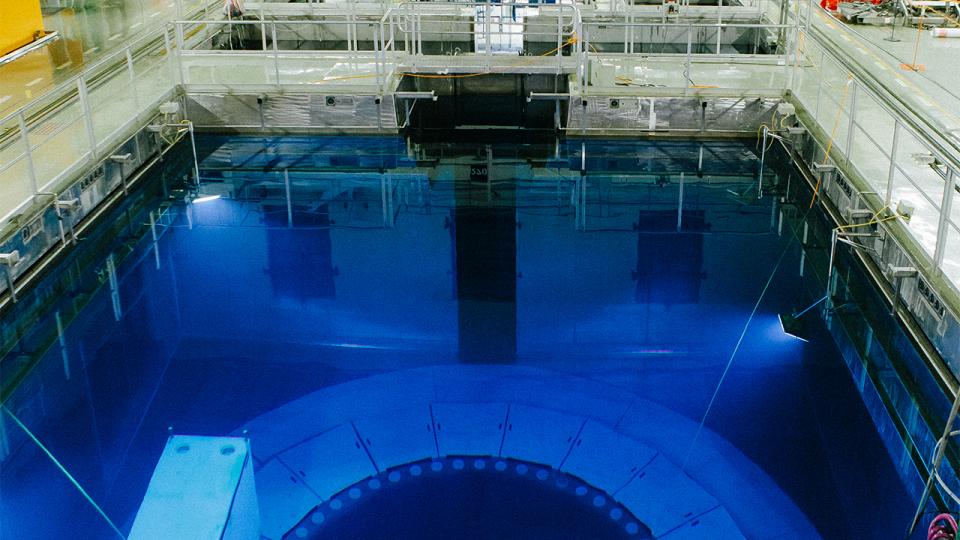

Boiling water reactor |

|

Reactor supplier |

Asea-Atom |

|

Turbine supplier |

Stal-Laval |

|

Commercial operations |

B1 1975, B2 1977 |

|

Thermal reactor output |

1800 MW |

|

Number of circulation circuits |

4 |

|

Operating pressure |

70 bar |

|

Total reactor cooling water flow |

7,700 kg/s |

|

Steam flow |

900 kg/s |

|

Steam pressure |

7.0 MPa |

|

Steam temperature |

286°C |

|

Feedwater temperature |

184°C |

|

Weight |

530 tons |

|

Total height |

20 m |

|

Inner diameter |

5.45 m |

|

Material thickness |

12.6 cm |

|

Number of fuel elements in reactor core |

444 |

|

Fuel weight per element |

UO2 181/172 kg |

|

Number of fuel rods per element |

100/96 |

|

Sealing material |

Zr2 |

|

Pellet diameter |

8.19 mm |

|

Type |

cruciform blade |

|

Number |

109 |

|

Absorber material |

hafnium, boron carbide |

|

Control drive type |

electro-hydraulic |

|

Type |

enclosed centrifugal pumps |

|

Number |

4 |

|

Flow |

2.55 m³/s |

|

Lifting height |

55 m |

Turbine

- In-depth data about the turbine units. One unit per block. One turbine unit is connected to the reactor. The turbine unit consists of one high-pressure turbine and three low-pressure turbines that are mounted on the same shaft as the generator.

- The turbine buildings also contain the condenser, cooling water and feedwater pumps.

|

Net output |

615 MW |

|

Coefficient of utilization |

33.7% |

|

Steam flow |

813 kg/s |

|

Moisture content in primary steam |

0.004% |

|

Pressure/temperature before high-pressure turbine, MPa/°C |

6.1/284°C |

|

Pressure/temperature after high-pressure turbine, MPa/°C |

0.65/162°C |

|

Pressure/temperature before low-pressure turbine, MPa/°C |

0.62/256°C |

|

Pressure/temperature in condenser, MPa/°C |

0.043/30°C |

|

External moisture separator and intermediate overheating up to 256°C |

|

|

Number of outlets and area per turbine |

6x8.5 m² |

|

Outlet blade length |

95 cm |

|

Number of revolutions |

3,000 rpm |

|

Flow, condenser cooling water |

22.2 m³/s |

|

Temperature increase in condenser cooling water |

11.8°C |

|

Cooling water pumps/turbine |

4 |

|

Dumping capacity |

100% |

|

Total length of turbine unit: |

50 m |

Electrical equipment

- Key facts about the electricity generator, transformer and reserve-power diesels.

- An electricity generator is linked to each turbine at Barsebäck.

- With two turbines – one on each block – there were two generators.

|

Brand |

ASEA |

|

Number |

1 |

|

Force output |

620 MW |

|

Rated voltage |

17.5 kV |

|

Rated output |

710 MVA |

|

Stator cooling |

water |

|

Rotor cooling |

water |

|

Number |

1 |

|

Rated voltage |

17.5/410 kV |

|

Rated output |

700 MVA |

|

Number |

4 |

|

Motor manufacturer |

MTV |

|

Nominal output |

1,600 kW |

|

Rated voltage |

6.3 kV |

|

Rated output |

2.1 MVA |

|

Number of revolutions |

1,500 rpm |

Decommissioning and demolition

- Since April 2020, Barsebäcksverket has been undergoing dismantling and demolition. The dismantling process and removal of radioactive materials and large components within the plant will continue until 2028.

- The directives of the Swedish Radiation Safety Authority (SSM) continue to impose stringent requirements on our operations – we are still classified as a nuclear facility, even if the power plant is shut down and no nuclear fuel remains.

- We are also working with the handling and transportation of operational waste to the SFR final repository in Forsmark, and thereby continuously reducing the range of activities at the plant.

- We are also continuing with our sales operations – components that we no longer need can in some cases be reused in other nuclear facilities or for other industries.

Find out more

The method used for generating electricity in a nuclear power plant is the same as with a coal power plant or a bioenergy power plant.

History of the industry from 1965 to the present.