Environment

We work proactively to reduce our impact on the environment and to live up to the requirements and expectations imposed on us by government agencies and the community.

Barsebäck Kraft AB has a permit from the Land and Environment Court for conducting dismantling and demolition work. The permit includes port operations and the reuse of waste for purposes related to the plant. The permit regulates what we may do and includes conditions which we must adhere to regarding, for example, noise, waste and chemical products. The County Administrative Board of Skåne is the supervisory authority and verifies our compliance with the requirements stipulated in our environmental permit. The environmental permit is valid until the demolition is completed.

As of 2002, Barsebäcksverket has been environmentally classified pursuant to ISO 14001. This entails that our manner of handling environmental issues and our environmental impact is subject to review by auditors and government agencies.

We care about people and the environment

Health and safety are two paramount issues for us. Consequently, we have created a plan for how to work with these issues:

-

safety always comes first

-

we safeguard people’s health

-

we protect our personnel and our assets

-

we act responsibly to reduce our environmental impact

We are aware that all accidents that can occur at other worksites can also happen at a nuclear power plant (fire, lightning, etc.) All employees at our facility (in-house and outsourced) attend special courses on radiological protection, first-aid with CPR and fire prevention, as well as customized training within safety culture – everything to reduce the risk of incidents.

Follow Pia, who is carrying out demolition work

Occupational health and safety

Our guiding star is: “when we feel well, we perform well.” Barsebäck Kraft has been certified under ISO 45001 for occupational health and safety since June 2021.

The goals of Barsebäck Kraft and the Group

Leadership, identity and culture

Utilize education and coaching to increase the competence of managers and decision-makers with regard to the environment and occupational health and safety. Increase the knowledge of managers about mental health and how to reach out to employees. Proactively create an inclusive work approach.

Specific technical and plant objectives

Maintain awareness about the significance of reporting and investigating risk observations and incidents, with the aim of preventing future accidents and ensuring efficient and safe work methods.

Focus areas

-

Balance between work and leisure time

-

Organization and division of responsibilities

-

Collaboration

-

Competence

-

Relevant risk assessments linked to efficient remedial work

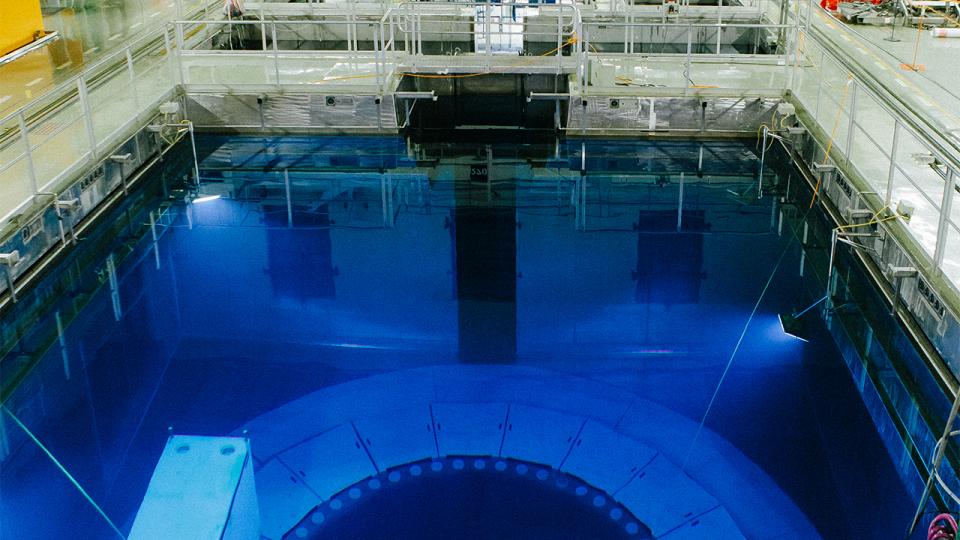

Radiation is a natural part of the work environment at a nuclear power plant. We work continuously with radiation protection, such as by measuring, checking for and preventing unnecessary exposure. Read more about how we process radioactive waste.

Find out more

We work with continuous improvements by involving all of our employees in our systematic HSE work. Find out more in our HSE policy.

Why are nuclear power plants being demolished in Sweden?

The method used for generating electricity in a nuclear power plant is the same as with a coal power plant or a bioenergy power plant.