Hydrogen in Sweden

What is Hydrogen?

Hydrogen is not an energy source in itself, but just like electricity it is an energy carrier. It can therefore not be determined to be renewable, fossil-free or fossil without knowledge about the production process – it can be any of these things, depending entirely on how it is manufactured. Hydrogen, H2, is a chemical compound of two hydrogen atoms, the most common element we know of. Hydrogen is odorless, colorless, and highly flammable. Hydrogen, however, is very volatile, which means that it dissolves quickly in the air and becomes harmless.

When hydrogen gas meets oxygen, large amounts of energy is released. The residual product is ordinary water, since hydrogen, H2, reacts with oxygen, O, to form H2O.

To be able to use hydrogen for fuel, electricity or heat, an energy converter is needed. It can be a fuel cell, a type of energy converter that can be used to transform the chemical energy of hydrogen into electricity. The residual products are simply water and heat, that can be recovered and used.

What is hydrogen and why is it so important?

Climate change in society is one of the greatest challenges of our time. We need many different solutions that together reduce emissions and create a fossil-free future. Hydrogen is one of these solutions.

How is hydrogen made?

The most common way of producing hydrogen is either through so-called steam reforming, methane pyrolysis or electrolysis.

Steam reforming

The most common method is steam reforming of natural gas. The natural gas is heated to temperatures between 700 and 1,100 degrees Celsius, which in combination with a catalyst causes water vapor to react with the methane in the natural gas (CH4) to form carbon dioxide and hydrogen gas. The large disadvantage of this method is that it creates carbon dioxide emissions. The advantage is that it costs less.

Methane pyrolysis

In methane pyrolysis, natural gas is heated to over a thousand degrees and allowed to travel through a catalyst of molten metal. The methane (CH4) is divided in two hydrogen molecules and one carbon atom. The carbon atom can then be stored in solid form and is not released into the atmosphere. The advantage of this method is that it converts a fossil fuel into hydrogen without creating carbon dioxide. The method is relatively new and needs to be further developed in order to be useful on an industrial scale.

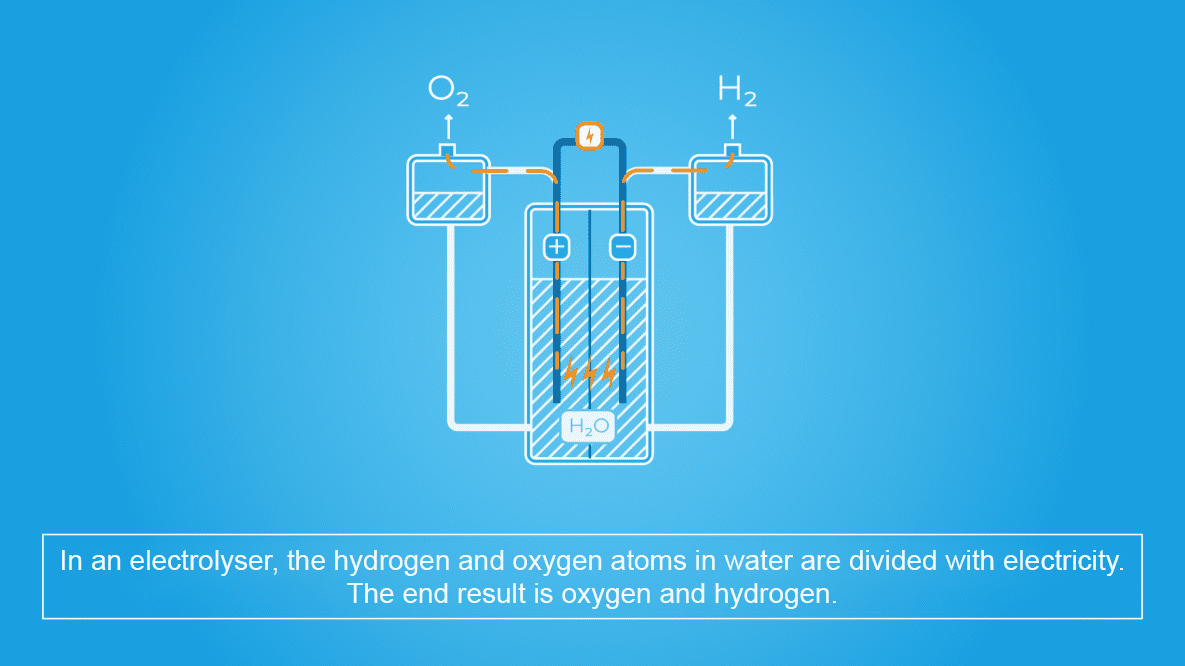

Electrolysis

In an electrolyzer, water is broken down into hydrogen and oxygen with the help of electricity. There are two electrodes in the electrolyzer - one with a positive (anode) and one with a negative (cathode) charge. The cathode is often covered with platinum so that positively charged atoms that migrate over can be reduced, which occurs when they receive electrons from the surface of the cathode. When they are reduced, hydrogen is formed. At the anode, negatively charged atoms leave electrons. This creates oxidation, forming oxygen.

If fossil-free electricity is used in the electrolyzer, the hydrogen gas will be climate-friendly. The disadvantage is that the efficiency is relatively low – about 20-30 percent of the energy is lost in the conversion from electricity to hydrogen. However, research and development initiatives are constantly improving the efficiency. By 2030, there are estimates that losses will be reduced to between 14 and 18 percent.

What can hydrogen be used for?

Hydrogen is an energy carrier with many different uses. In industry, hydrogen has been used as a raw material for over 100 years, mainly in the chemical industry, for example to produce ammonia.

Hydrogen in combination with a fuel cell can, for example, be used to power a vehicle or as a reserve power system for base stations or telephone exchanges, to reduce the vulnerability of the telephone network during storms or other disturbances.

In Sweden, the assessment is that hydrogen primarily will be used in the process industry, e.g. to produce fossil-free steel. Heavy transports that are difficult to electrify is another area with great potential. A third possible area of usage is to use hydrogen to even out peaks and low points in the electricity system.

In Sweden, the role of hydrogen has previously not been very large, but the interest has increased as the EU has decided to invest heavily in hydrogen.

Process industry

The hydrogen gas can be used to replace fossil fuels in the process industry, among other things. In the production of steel, for example, large amounts of coal and natural gas is used today. They react chemically with the iron ore, and release large amounts of greenhouse gases in the process. The challenge has been to find a fossil-free manufacturing method. This is where the hydrogen becomes relevant.

Read more about Uniper Project Air, where Uniper will produce hydrogen that the chemical company Perstorp can use in its production. The switch to hydrogen can reduce Perstorp’s emissions by 500,000 metric tons of carbon dioxide per year.

Heavy transport

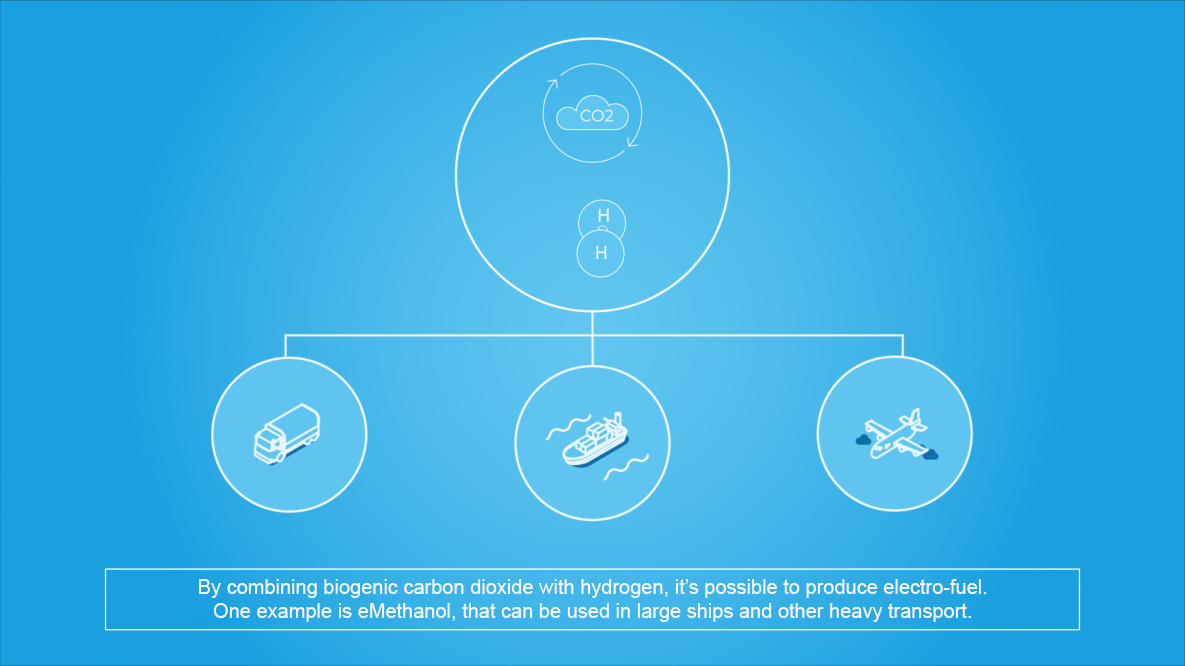

For cars and other relatively light transportation methods, electricity is a good solution. But for ships, heavy trucks and aircraft, batteries with sufficient capacity are usually too heavy and too expensive. If you combine biogenic carbon dioxide with fossil-free hydrogen, you can produce so-called electro-fuels, for example eMethanol, which can be used in a combustion engine. Biogenic carbon dioxide comes from carbon atoms that are part of a short cycle, for example based on forest product residues or other biological materials – as opposed to fossil fuels.

Read more about Uniper's work with Liquid Wind to produce eMethanol for heavy transport. In total, emissions can through this project be reduced by 100,000 metric tons of carbon dioxide every year.

Read more about the Bothnia Link H2, a project Uniper is running together with ABB and the Port of Luleå, which, among other things, is intended to produce hydrogen-based fuels for large ships.

Energy storage in the electrical system

As the proportion of intermittent and weather-dependent electricity production in the electricity system increases, so does the need for storage that can help even out peaks and low points in production. Right now, hydropower dams act as large batteries that can be used when the need arises. In the future, hydropower will not be enough, creating the need for other solutions.

By connecting an electrolyzer to a power plant and producing hydrogen when there is a surplus of electricity in the system, electricity production can be optimized based on market needs. The hydrogen gas is stored and converted back to electricity when the electricity demand is greater than the production capacity. One challenge is that the efficiency will be low since the electricity has to be converted to hydrogen, and then back to electricity again – with conversion losses in both directions. Therefore, Uniper estimates that there will be no large-scale use of hydrogen in the electricity system in the nearest few decades.

Uniper and hydrogen

Uniper is one of Europe’s leading hydrogen actors, working with several innovative hydrogen projects in Sweden. As of now, substantial progress is being made in the hydrogen area, enabling the transition to a fossil-free future.

Uniper has several hydrogen plants that are already in operation.

The electrolysis plant in Hamburg has an output of 1.5 MW and produces hydrogen that is delivered to the local gas network.

The electrolyzer in Falkenhagen is the world's first pilot plant for storing wind power in the regular natural gas network. Energy from wind turbines is converted in the plant by electrolysis to hydrogen gas which is then fed via a pipeline to the natural gas network. This way, the energy from wind power can be stored and be available for the electricity, heating, and transport markets. During the first year of the pilot project, 2 million kWh of hydrogen was discharged into the gas network in Germany.

The plant in Falkenhagen has also been expanded with a methanation plant that produces fossil-free methane for use in the natural gas network.

Uniper’s investments in hydrogen

Uniper is investing in hydrogen as a tool for a transition to fossil freedom in Sweden too. At OKG outside Oskarshamn, we have had fossil-free hydrogen production since 1992. The electrolyzer has a capacity of 0.7 MW and the hydrogen is produced with the help of electricity from the nuclear power plant and water from the nuclear power plant's own waterworks. Hydrogen is used at OKG for cooling generators, while surplus production is currently sold on a completely commercial basis.

Project AIR is a collaborative project between the chemical company Perstorp an Uniper. Uniper will supply hydrogen to the methanol plant that Perstorp is building in Stenungsund. The electrolyzer will have a capacity of 25 MW, making it one of the largest in Europe. Thanks to the fossil-free hydrogen, carbon dioxide emissions are estimated to be reduced by approximately 500,000 metric tons per year.

Uniper is also the third largest owner in the company Liquid Wind, that will produce the electro-fuel eMethanol using hydrogen, wind power electricity and biogenic carbon dioxide. The first facility is being built in Örnsköldsvik and is expected to be completed by 2023 or 2024. The plant will produce 50,000 metric tons of eMethanol per year and is estimated to reduce carbon dioxide emissions by 100,000 metric tons per year.

BotnialänkenH2 is an interesting project that Uniper is running together with ABB and the Port of Luleå. The plan is to establish a regional hydrogen hub in Luleå where hydrogen is produced using wind power, and where the hydrogen can be used in the regional process industry, converted into electro-fuel for ships, or exported.

Hydrogen in Sweden

Sweden is lagging behind in global and European hydrogen development. Previously, there has been no elaborate strategy for hydrogen in Sweden. The government initiative Fossil Free Sweden developed a hydrogen strategy in 2020, that laid the groundwork for the progress that the Swedish Energy Agency has done on behalf of the government to develop a Swedish hydrogen strategy. The strategy was published late 2021.

To make sure that the Swedish hydrogen strategy provides good conditions for hydrogen, the government needs to consider a number of crucial choices. This can be geography and investments in infrastructure, or technology and the need for technological neutrality. Further, there is a need for strategy decisions in financing and market models. The most important principle is that all fossil-free hydrogen must be treated equally. Uniper is optimistic about the development of hydrogen in the coming years, but many challenges remain to be solved. Join us on our and hydrogen’s journey!

Project Air

An initiative to produce sustainable methanol which will substitute the fossil methanol at large chemical site in Sweden.

Find out more

In the Swedish electricity system, hydro power is currently Sweden’s largest source of renewable energy and accounts for approximately 45% of Swedish electricity generation.

Uniper Sweden has nine gas turbines that are included in the disturbance reserve. The gas turbines are crucial to Sweden’s energy security and mitigate the consequences of any unexpected events in the electricity system, thereby preventing large-scale disruptions from occurring.

Due to low electricity prices and alternative heating production in the area of Malmö, Öresundsverket has not been available for the electricity market since 2017.