The risks of nuclear power

As with all other major industries, there are risks associated with nuclear power. Nuclear power is a very technologically complicated industry that requires well-educated and competent personnel.

The greatest drawback of nuclear power operations is the creation of radioactive substances. A serious accident could result in the release of radioactive substances that could impact the environment. Therefore, a nuclear power plant must be built to block the uncontrolled discharge of radioactive substances.

The probability of a serious accident is very low, particularly in Sweden, with its stringent safety requirements. There have been no serious accidents involving radioactive leaks from Swedish nuclear power plants.

Safety work

The safety work at a nuclear power plant is based on three steps:

1. Preventing errors

2. Preventing any errors from resulting in a breakdown, i.e., by means of various monitoring and safety systems

3. Alleviating the consequences in the event of error, i.e., preventing radioactive leakage.

How do we prevent error?

High quality materials and construction techniques

All important sections of a Swedish nuclear power plant are of high-quality construction and have wide safety margins. Every year, major investments are made to keep the plants in excellent condition.

Regular controls and tests

Every summer, the reactors are shut down for fuel replacement and review. Inspections and tests are performed on the equipment and safety systems. Some controls and tests are also conducted at other times of the year. Everyone who works inside nuclear facilities must adhere to highly detailed safety regulations.

Well-educated personnel

All employees who are to work in a nuclear power plant must undergo special training in, for example, radiological protection. Operators undergo training regularly in identical replicas of control rooms.

30-minute rule

In the event of an error, everything that must be done within 30 minutes is implemented automatically. The rule is in place to allow the personnel to have the time to think.

Reactors cannot melt down

The reactors we have in Sweden cannot melt down, i.e., increase their output uncontrollably. They are built to autonomously shut down when something is wrong.

Safety systems

Swedish nuclear power plants are built so that in the event of human error, nothing serious will happen. Numerous monitoring and safety systems are in place to prevent any errors from resulting in a breakdown.

Four-second reactor trip system

In the event of an error, the reactor is shut down automatically. Control rods are inserted into the reactor core to halt the ongoing nuclear fission within seconds. However, some “decay power” will remain in the reactor due to radioactive fission products generating heat. Consequently, a reactor must be cooled for an extensive period of time following a reactor trip.

Redundant safety systems provide increased protection

Most of a nuclear power plant’s safety systems are designed to cool the reactor and ensure that excessive pressure does not build up in the containment building.

How the systems work:

Redundancy: There are usually two or more safety systems in place designed to accomplish the same task.

Example: There are several pumps that provide the reactor with water.

Diversification: Each utilizes a different technical solution so that not all of them will be impacted by the same error.

Example: The pumps are of different brands.

Separation: They are distributed throughout the plant so that not all of them will be disabled in the event of a fire, for example.

Example: The pumps are located in different rooms.

If the first safety system fails, the second takes over. If the second one fails too, then the third system takes over and so forth. The risk that an error will elude all of the safety systems is minimal.

Electricity from many sources

It is important for a nuclear power plant to have electricity for its pumps, which provide the reactor with cooling water. Therefore, if a power failure should occur at the plant, there are several alternatives in place:

- electricity from external power lines

- fixed and mobile diesel generators

- battery room with several hundred batteries, to manage 30 minutes of operation

- gas turbines outside the power plant

Barriers

In addition to a nuclear power plant’s safety systems, there are barriers to protect the environment in the event of a serious breakdown. Shutting down a reactor primarily entails inserting control rods and halting the fission process. This can be done by means of several independent systems and as quickly as within four seconds.

In the reactor building

Reactor safety primarily pertains to keeping the fuel elements under water and thereby keeping them cooled. This is necessary, due to the fuel elements giving off residual heat. If the regular cooling system should fail, there are several other emergency cooling systems in place that can cool the fuel and depressurize the reactor vessel. The systems may obtain their power supply from several independent sources. If the emergency cooling systems fail and the reactor vessel’s water level should fall below the level of the fuel, the temperature of the fuel core will rise and the pressure in the reactor vessel will increase.

The reactor vessel is made of thick steel and can withstand high pressure for a time, even if deprived of new cooling water. The high pressure is caused by steam. The fuel itself and its enclosure which is made of zirconium, can withstand extremely high temperatures. This delays the time it takes for the fuel to melt. In the event that the fuel melts, the steam will be mixed with radioactive particles and gases.

The containment building encloses the reactor and is made of one-meter thick pressure-proof concrete with a cast steel plate. The enclosure can withstand the highest pressures that could form during an extended and serious breakdown. The reactor building itself is also made of thick concrete and functions as a barrier to the surroundings. If the pressure in the enclosure should become too high, there is a passive pressure-release system with a filtration function.

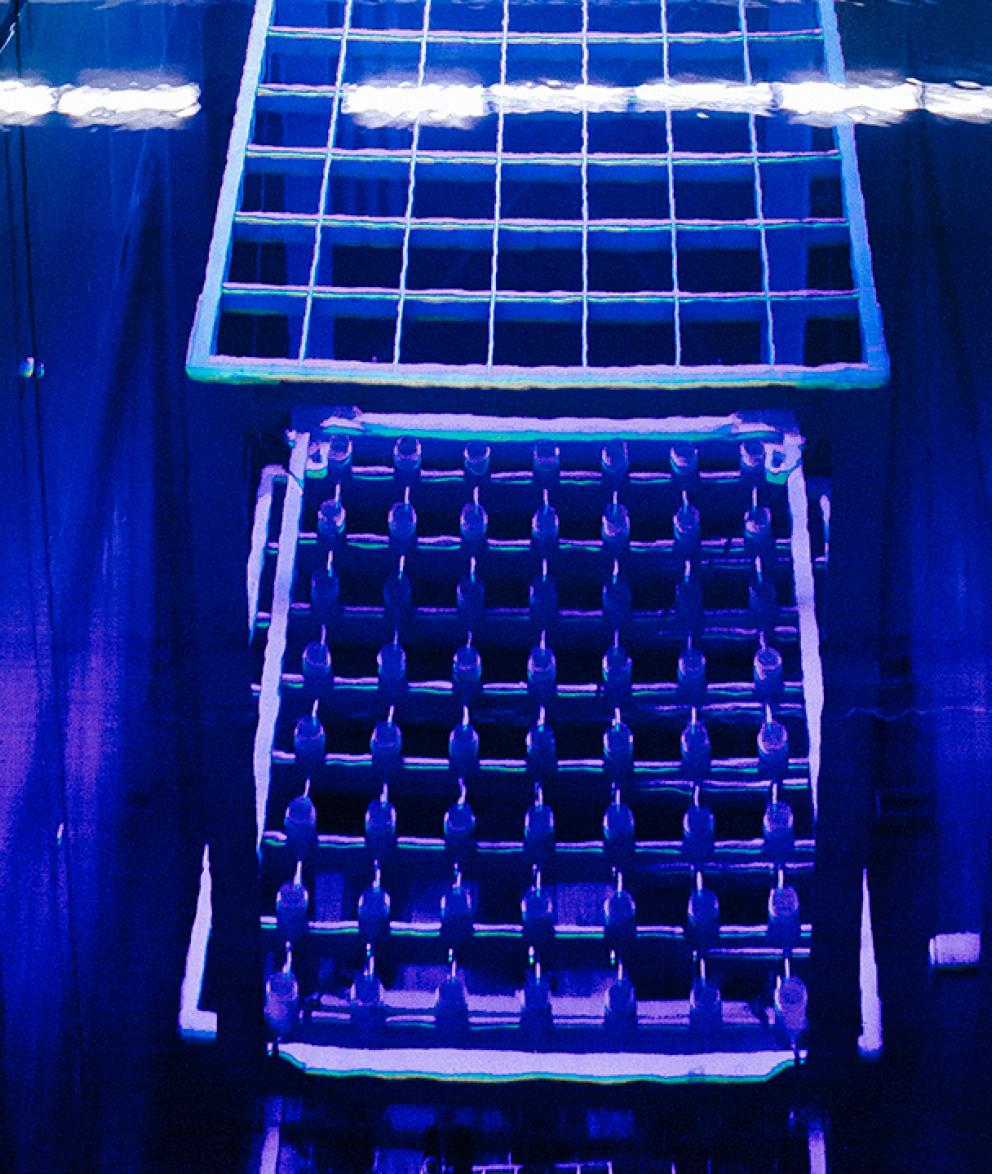

Filtration system at Barsebäck

The excess pressure in the enclosure automatically opens a valve and the radioactive mixture of gases is forced out through a gravel filter. The radioactive substances attach themselves to the gravel through a natural process, limiting radioactive discharges into the surroundings to 0.1% of the original level, thereby rendering the depressurization and discharge harmless to the environment.

At other nuclear power plants in Sweden, depressurization is filtered through water. These water scrubbers are at least as effective as gravel filters. Both types of breakdown filters are Swedish inventions.

Find out more

Radiation is everywhere around us. We are exposed to radiation from space, from bedrock and our own bodies every day. Humans have also created artificial sources of radiation.

Some insight into how we dismantle a nuclear power plant.